How Thermo Forming Works

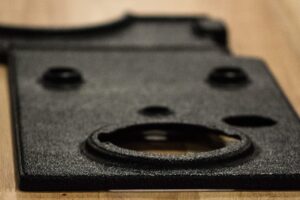

Thermo forming starts with a plastic sheet. The sheet is heated until it becomes flexible, then shaped over a mold through vacuum, pressure, or mechanical force. Once it cools, the part holds its final shape and moves on to trimming and finishing. This makes it possible to thermo form plastic into a wide range of parts—from clean, shallow trays to deep, detailed housings. The process supports quick changeovers and practical tooling costs, which makes it a strong fit for both prototypes and repeat production.

Our Capabilities

Plastic Creations, LTD offers vacuum forming, pressure forming, and drape forming. These methods give us control over detail level, surface finish, and part strength. We work with sheets up to large sizes, which gives you flexibility if your project requires bigger components. Whether you need a single prototype or thousands of repeat parts, we set up the right forming approach to keep your project efficient and consistent.

- Vacuum Forming: Vacuum forming pulls the heated sheet across a mold using suction. It’s a solid option for general parts, cost-efficient runs, and projects that do not need sharp detailing. Many customers choose this for covers, trays, guards, and lightweight assemblies.

- Pressure Forming: Pressure forming adds compressed air to achieve more defined surfaces. If your part needs crisp lines, improved aesthetics, or a more refined appearance, this method delivers those results.

- Drape Forming: Drape forming is used for curved or rounded parts. The heated sheet is placed over a shaped tool and allowed to settle into the form. It’s often chosen for panels, cylinders, and components with smooth arcs.

Materials We Work With

We thermo form plastic in a wide selection of materials including ABS, PVC, polycarbonate, PETG, HDPE, and HIPS. Each material offers different strengths—impact resistance, clarity, temperature stability, or cost-efficiency. If you’re still deciding which material fits your job, we can help narrow that down so your part performs the way you expect.

Why Choose Thermo Forming

Thermo forming offers practical benefits for many applications. Tooling costs stay lower than other molding methods, which reduces lead time and helps you move through prototypes quickly. The process can support large parts without heavy molds. It also works well for medium-size production runs where flexibility and speed matter. If you need precise trimming, holes, cutouts, or assembly, we handle that in-house.

Industries We Support

We produce components for automotive, industrial equipment, medical devices, retail displays, packaging, and consumer products. If your parts require consistent forming, reliable materials, or repeatable results, thermo forming provides a direct path to production.

Why Work With Plastic Creations, LTD

We focus on clarity, communication, and predictable production. Our team supports both early-stage concepts and long-term production programs. If you need help shaping a thermo form plastic part or want advice on the best process for your design, we keep the conversation easy and straightforward.

If you’re planning a new project or need a quote, reach out to our team. We’re ready to help you move your thermo forming job forward with practical solutions and dependable production.